Avicenna Journal of Clinical Microbiology and Infection. 10(2):58-64.

doi: 10.34172/ajcmi.3477

Original Article

Evaluation of Antimicrobial Effects of Nisin/Chitosan Composite on Cotton Fabric Textile

Mahboubeh Mirhosseini 1, *  , Maede Afzali 1, 2

, Maede Afzali 1, 2  , Hosein Molla Hoseini 3

, Hosein Molla Hoseini 3  , Sara Khaleghizadeh 1

, Sara Khaleghizadeh 1

Author information:

1Department of Biology, Payame Noor University, Tehran, Iran

2Tissue Engineering Department, School of Advanced Technologies in Medicine, Tehran University of Medical Sciences, Tehran, Iran

3District 1, Yazd Education and Training Organization, Yazd, Iran

Abstract

Background: The spread of nosocomial infections may be caused by contact between the patient’s body and textile materials used in medical practices. Therefore, it is necessary to use effective antimicrobial textiles to prevent the transmission of pathogenic bacteria and the occurrence of infections.

Methods: In this research, chitosan was utilized to bind nisin to the surface of cotton fabric. The binding properties of nisin on the fabric were explored using Fourier transform infrared spectroscopy (FTIR) and scanning electron microscopy (SEM) techniques. The antibacterial effectiveness of fabrics against Escherichia coli, Pseudomonas aeruginosa, Staphylococcus aureus, Bacillus cereus, Listeria monocytogenes, and Enterococcus faecalis was measured. The durability of the antimicrobial properties of these fabrics was checked after 10 washing cycles. Additionally, the toxicity of this fabric on fibroblast cells was determined using the MTT colorimetry after 7 days.

Results: Chitosan-nisin formed a homogeneous and colorless layer on the cotton fabric. Antibacterial results showed that nisin improved the antibacterial effect of coated fabrics against all tested bacteria. The antimicrobial properties of the fabric coated with chitosan-nisin were maintained at approximately 100%, 17.26%, 8.55%, 2.98%, 1.38%, and 17.4% efficacy against B. cereus, S. aureus, E. faecalis, L. monocytogenes, E. coli, and P. aeruginosa, respectively. Furthermore, the chitosan-nisin coating demonstrated no significant toxic effect on fibroblast cells even after 1 week.

Conclusion: The results suggest that the chitosan-nisin coating could be utilized in the production of medical textiles and underwear. Moreover, it offers an innovative solution to protect human health and the environment.

Keywords: Antibacterial coating, Biomaterial, Chitosan, Nisin, Textile finishing process

Copyright and License Information

© 2023 The Author(s); Published by Hamadan University of Medical Sciences.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (

https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Please cite this article as follows: Mirhosseini M, Afzali M, Molla Hoseini H, khaleghizadeh S. Evaluation of antimicrobial effects of nisin/chitosan composite on cotton fabric textile. Avicenna J Clin Microbiol Infect. 2023; 10(2):58-64. doi:10.34172/ajcmi.3477

Introduction

Activated textiles have opened up new avenues of application beyond traditional uses in the textile industry. These textiles now possess novel functions, such as enhanced antimicrobial properties. As a result, they have received recognition in various sectors, including healthcare, industry, sportswear, and home textiles (1). Recent advancements in the production of antibacterial textiles have garnered significant attention due to their potential to address critical health challenges associated with bacterial overgrowth. Extensive research has been conducted in the field, focusing on the incorporation of synthetic and toxic materials, including nano-silver, triclosan, and various metals and organic substances, to develop antimicrobial fabrics (2-6). These fabrics function by binding to intracellular proteins, thereby inactivating them and effectively killing bacteria. Additionally, the utilization of these chemicals allows for an increased presence of heavy metals in these textiles (1). The application of heavy metals in antimicrobial textiles is restricted due to various environmental regulations and standards. Therefore, it is advisable to utilize natural polymers like chitin and chitosan for the production of environmentally friendly and safe antimicrobial fabrics. Chitosan, being the second most abundant biological polymer after cellulose, is a derivative of chitin which is commonly derived from the exoskeleton and shells of certain crustaceans (1,7-9). Chitosan is a biocompatible polymer that possesses various physiological and biochemical properties, including ion-separating effects, anti-clostridium activity, and antimicrobial properties. It has been demonstrated to inhibit the growth of a wide range of fungi and bacteria. The antimicrobial efficacy of chitosan is strongly influenced by factors such as the degree of positive charge, N-deacetylation, the nature of chemical modifications, and the average degree of polymerization (1,10). The pH of the environment can influence the positive charge of the amine groups of chitosan (1). Chitosan finds application in a variety of fields owing to its structure, which contains hydroxyl and active amino groups that can be readily modified and activated. These active groups make chitosan suitable for textile finishing and dyeing. Moreover, the antimicrobial, antitumor, anticancer, and antioxidant properties of chitosan make it valuable in diverse medical disciplines (8,11,12). When cotton is supplemented with different cross-linking agents (such as BTCA, glyoxal, and glutaraldehyde) in the presence of chitosan, it exhibits a broad spectrum of antimicrobial activity against fungi, as well as Gram-positive and Gram-negative bacteria (13). Therefore, the application of chitosan coating on textile materials can effectively enhance their antimicrobial properties (1). Nisin, a bacteriocin produced by Lactococcus lactis subspecies lactis, has gained approval as a food preservative from regulatory bodies such as the World Health Organization and the United States Food and Drug Administration (7,14-18). Nisin, a hydrophobic compound, undergoes degradation by metabisulfite, titanium oxide, and certain proteolytic enzymes. It exhibits remarkable efficacy against gram-positive bacteria, particularly spore-forming types, while being ineffective against gram-negative bacteria and fungi. Nisin is widely employed as a food preservative due to its favorable characteristics, including non-toxicity, natural origin, excellent storage stability, resistance to digestive enzymes, and absence of alterations in taste and odor. Additionally, nisin holds therapeutic potential in the management of infectious diseases; however, it is poorly absorbed through inhalation, dermal application, and oral administration. The rapid breakdown of nisin by protease enzymes renders oral administration impractical. Therefore, the optimal utilization of nisin for disease treatment involves its application in superficial and localized conditions such as oral cavity, skin, respiratory system, stomach, intestine, or mammary gland diseases (18). Meanwhile, nisin and chitosan are antimicrobial and non-toxic, making them suitable for application on various surfaces that are exposed to harmful microorganisms. Consequently, in this study, we sought to enhance the antibacterial activity against pathogenic bacteria by coating cotton fabric samples with nisin, utilizing chitosan as a cross-linker. It is worth noting that numerous studies have been conducted recently in order to develop textile samples with antimicrobial properties (2-6,12). Montaser and Mahmoud conducted an evaluation of metal polyvinyl acetate nanocomposite grafted with chitosan, aiming to develop multifunctional cotton fabrics with enhanced properties. The findings indicated that the samples treated with the copolymer exhibited the highest level of antibacterial properties. Additionally, when the copolymer was doped with TiO2 and TiO2/ZnO, it resulted in a reduced contact angle and positively influenced the photocatalytic performance of the fabric (9). Gouda and Hebeish conducted a study on the antimicrobial finishing of cotton fabric using CuO/chitosan nanocomposite (19). In another study, it was demonstrated that the application of chitosan-silver nanoparticles onto textiles significantly improved their antimicrobial and antioxidant properties. The findings indicated that chitosan silver nanoparticles could potentially serve as a safer and more environmentally friendly alternative to conventional chemical active agents (20). Wei et al conducted a study where they developed chitosan quaternary ammonium salt nanoparticles to modify cotton fabric. The modified cotton fabric exhibited remarkable wrinkle resistance, remaining intact even after undergoing 50 repeated washings. Moreover, it demonstrated effective antibacterial activity against Staphylococcus aureus and Escherichia coli. Additionally, the modified cotton fabric displayed enhanced resistance to shrinkage, with an increased contact angle. Notably, the whiteness and mechanical properties of the fabric remained unaffected by the modification process (21). To date, there have been no reported studies on the utilization of nisin in antimicrobial textile applications. Therefore, this study aimed to investigate the coating of fabric surfaces with nisin via chitosan. The antibacterial activity of fabric samples coated with nisin-chitosan was assessed, along with an examination of the cytotoxicity of the antibacterial textile on fibroblast cells. Additionally, the durability of the coating on cotton fabric was evaluated.

Materials and Methods

Bacterial Strains, Media, and Materials

The following bacterial strains were utilized in this investigation: Escherichia coli PTCC1394, Pseudomonas aeruginosa PTCC 1074 (gram-negative), and Staphylococcus aureus PTCC1431, Bacillus cereus PTCC1015, Listeria monocytogenes PTCC19112, and Enterococcus faecalis PTCC 1237 (gram-positive). These strains were obtained from the culture collection department, Tehran, Iran. Nisin was procured from Sigma. Bleached woven 100% cotton fabric (with a weight of 150 g/m2 and a warp/weft density of 25/21 threads/cm) was purchased from Yazd Baft Company in Yazd, Iran. Chitosan was synthesized from shrimp shells based on a previous study (22).

The finishing applications were conducted on a laboratory scale. Cotton samples were coated for 30 minutes in a solution containing 2.56 mg/mL of nisin and 1.5% (w/v) chitosan. This was followed by a dry process at 100 °C and a cure at 150 °C for 2 minutes (9,13).

Characterization of the Coated Fabrics

The surface structure of the coated fabrics was examined using scanning electron microscopy (SEM) (Phenom ProX Desktop SEM, Thermo Fisher Scientific, USA). Additionally, the presence of nisin and chitosan (N/CS) in the coated fabrics was verified using the Fourier transform infrared spectroscopy (FTIR) technique (Shimadzu IRPrestige-21 spectrometer) (9,23).

Antibacterial Tests

Agar Diffusion Test

The agar diffusion method was employed to assess the antimicrobial properties of the fabric samples. Overnight cultures of E. coli, P. aeruginosa, S. aureus, B. cereus, L. monocytogenes, and E. faecalis bacteria were separately inoculated onto TSA plates. Subsequently, the coated fabrics were positioned on the inoculated plates and incubated at 37 °C for 24 hours. The zone of inhibition surrounding the coated fabrics was measured to indicate the antibacterial activity of each film sample (1,9,11,24).

The durability of the antibacterial activity was evaluated after subjecting the samples to 10 washing cycles (at 60 °C and 15 rpm for 15 minutes), which was done using a nonionic surfactant called golvash (Siavashn Company, Yazd, Iran) at a concentration of 2 g·L−1. The liquor to fabric ratio of 30:1 was maintained during the washing process.

Liquid Culture Test

Initially, the coated fabrics underwent a sterilization process using ultraviolet light for a duration of 1 hour. The antimicrobial activity of the coated samples was then assessed using the standard shake flask method (ASTME2149-01) recommended for fabric immobilized with active agents. Cotton fabrics were incubated with 5 mL of E. coli, P. aeruginosa, S. aureus, B. cereus, L. monocytogenes, and E. faecalis bacterial suspensions at 37 °C and 230 rpm. The bacterial concentration in each test was approximately 1 × 107 cells/mL. To determine the antimicrobial properties, samples were extracted from the test tubes before and after 24 hours of contact with the coated fabrics. These liquid cultures were serially diluted in sterile buffer suspension, plated on TSA, and incubated at 37 °C for 24 hours to determine the number of surviving bacteria. The antimicrobial activity, expressed as the percentage of bacterial reduction, was calculated by comparing the number of viable bacteria before and after contact with the coated textiles using the following formula:

Bacteria reduction (%) = ((A − B)/A) × 100

Where A and B represent the average number of bacteria before and after contact with the coated textiles, respectively (11,23).

The method mentioned above was used to assess the antimicrobial stability of the coated fabrics in the liquid medium after washing.(23).

Cytotoxicity Evaluation

The development and proliferation of cells on different coated fabric samples were assessed using the colorimetric MTT method after a period of 7 days. The coated fabric samples were placed in 24-well plates and sterilized under UV light for 1 hour. Subsequently, the samples were incubated with 3 mL of complete growth medium (DMEM) containing human foreskin fibroblasts (obtained from the Stem Cell Biology Research Center, Yazd Institute of Reproductive Sciences, Shahid Sadougi University of Medical Sciences, Yazd, Iran) in a CO2 incubator at a temperature of 37 °C for 1 and 7 days. At the end of these time intervals, the development and proliferation of fibroblast cells on the various coated fabric samples were determined using the colorimetric MTT method.

Statistical Analysis

SPSS version 19.0 was utilized for conducting all statistical analyses. The analysis of variance (ANOVA) and Duncan tests were employed to assess the differences between means, with a significance threshold of P < 0.05.

Results

Characterization of the Coated Cotton Fabrics

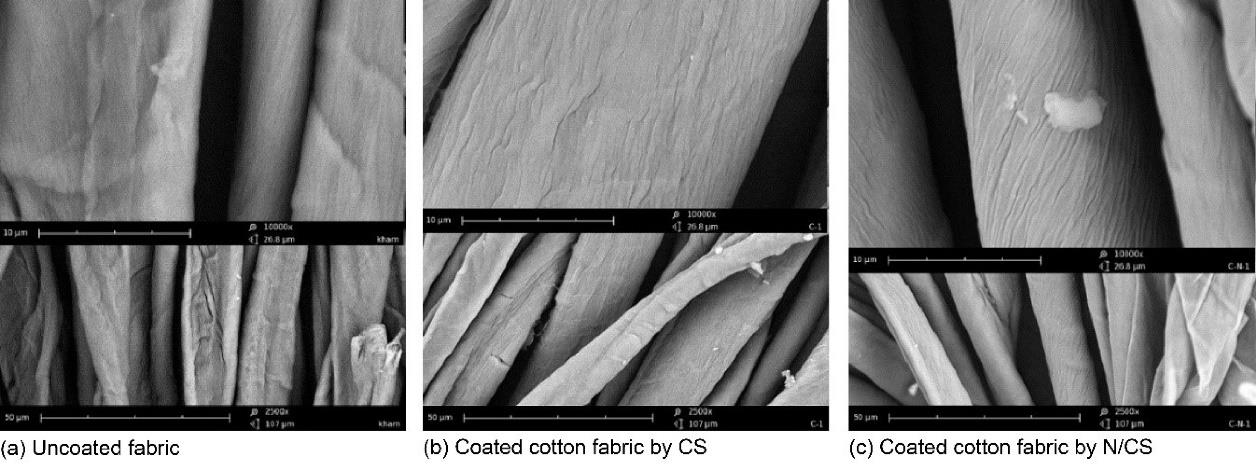

Figure 1 presents SEM images of both the treated cotton fabric and the untreated sample. From the images, it is evident that the coating is uniformly distributed across the fabric surface, indicating a homogeneous formation.

Figure 1.

Scanning Electron Microscope Images of a) Uncoated; b) Coated Cotton Fabric by CS; c) Coated Cotton Fabric by N/CS

.

Scanning Electron Microscope Images of a) Uncoated; b) Coated Cotton Fabric by CS; c) Coated Cotton Fabric by N/CS

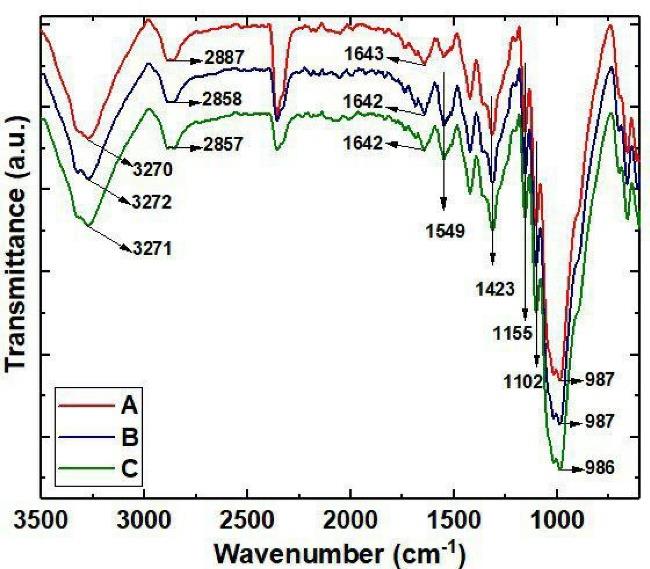

FTIR analysis was conducted to determine the presence of nisin/chitosan on cotton fabric treated with nisin/chitosan in the presence or absence of chitosan and nisin. The spectra obtained from the various antimicrobial coatings revealed similar patterns, as depicted in Figure 2. In the chitosan samples, broad peaks at 3400 cm-1 and 1030–1155 cm-1 were observed, corresponding to the stretching of O-H and N-H bonds, as well as C-O bonds, respectively. Additionally, absorption peaks at 2850–2950 cm-1, around 1550–1650 cm-1, and at 1400 cm-1 were detected, indicating C-H stretching, amine groups, and carboxyl groups, respectively. The presence of polysaccharide bands (C-O-C stretching) at 1060 cm-1 was also identified (7). Upon the introduction of nisin to the nisin/chitosan-coated fabric, several alterations in the FTIR spectra were noted. A new absorption peak at 3150–3450 cm-1 emerged, attributable to the presence of the -OH group of the peptides. Furthermore, additional peaks at 1656 cm-1 and 1537 cm-1 were observed, predominantly attributed to the amide I and amide II bands, respectively. These spectral changes can be directly associated with the peptide linkage in the fabric (7,14,15).

Figure 2.

FTIR Spectra of Coated Cotton Fabrics: (a) Uncoated; (b) Coated Cotton Fabric by CS; (c) Coated Cotton Fabric by N/CS.

.

FTIR Spectra of Coated Cotton Fabrics: (a) Uncoated; (b) Coated Cotton Fabric by CS; (c) Coated Cotton Fabric by N/CS.

Antibacterial Studies

The antibacterial activity of the coated cotton fabric, fixed-coated cotton fabric, and washed-coated cotton fabric was assessed against E. coli, P. aeruginosa, S. aureus, B. cereus, L. monocytogenes, and E. faecalis, in comparison to pure cotton fabric (Table 1, Figure 2). The results revealed that the coated cotton fabric, fixed-coated cotton fabric, and washed-coated cotton fabric did not exhibit any inhibition zone against L. monocytogenes and E. faecalis (P ≥ 0.05). However, these fabrics demonstrated inhibition zones against E. coli, P. aeruginosa, S. aureus, and B. cereus bacteria (P ≤ 0.05).

Table 1.

Inhibition Zone Diameters of Coated Cotton Fabric, Fixed-coated Cotton Fabric, and Washed-Coated Cotton Fabric in the Presence of E. coli, P. aeruginosa, S. aureus, B. cereus, L. monocytogenes,and E. faecalis

|

Samples

|

Strains

|

E. coli

(mm)

|

S. aureus

(mm)

|

B. cereus

(mm)

|

P. aeruginosa

(mm)

|

L. monocytogenes

(mm)

|

E. faecalis

(mm)

|

| Uncoated cotton fabric |

0 |

0 |

0 |

0 |

0 |

0 |

| Coated cotton fabric by CS (padding + drying) |

0 |

0 |

0 |

8 ± 0.19 |

0 |

0 |

| Fixed-coated cotton fabric by CS (Padding + Drying + Curing) |

0 |

0 |

0 |

8 ± 0.17 |

0 |

0 |

| Washed-coated cotton fabric by CS (padding + drying + curing + washing) |

0 |

0 |

0 |

8 ± 0.16 |

0 |

0 |

Coated cotton fabric by N/CS

(padding + drying)

|

18 ± 0.21 |

14 ± 0.1 |

21 ± 0.13 |

25 ± 0.19 |

0 |

0 |

| Fixed-coated cotton fabric by N/CS (padding + drying + curing) |

16 ± 0.13 |

13 ± 0.34 |

20 ± 0.09 |

22 ± 0.26 |

0 |

0 |

Washed-coated cotton fabric by N/CS

(padding + drying + curing + washing)

|

15 ± 0.25 |

16 ± 0.5 |

20 ± 0.43 |

20 ± 0.33 |

0 |

0 |

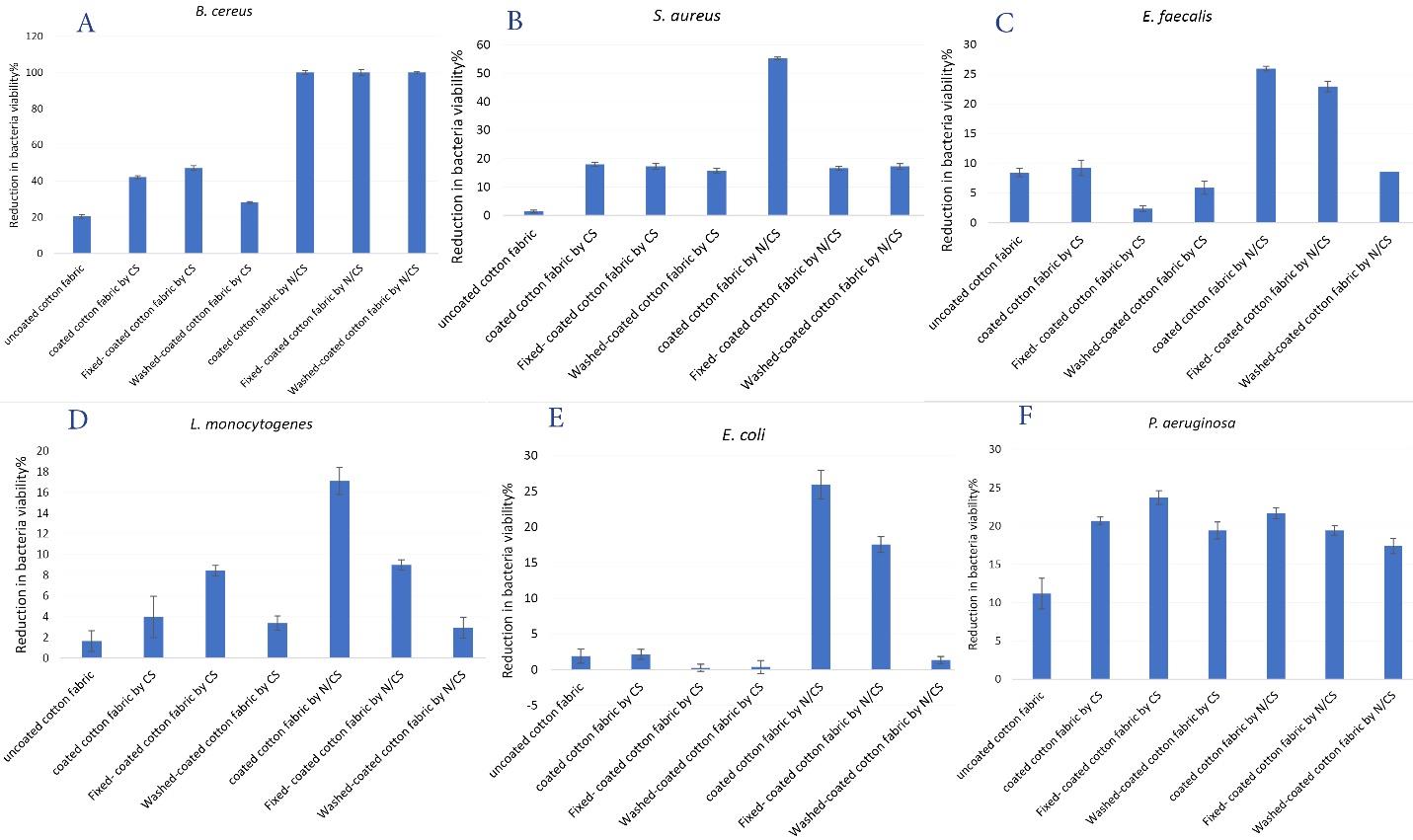

Subsequently, the antibacterial effectiveness of N/CS hybrid cotton fabrics was evaluated against 6 medically significant bacterial species in broth media. N/CS coatings exhibited a reduction in the viability of E. coli, P. aeruginosa, S. aureus, B. cereus, L. monocytogenes, and E. faecalis (Figure 2). As anticipated, the presence of nisin further enhanced the antibacterial impact of the coatings against all tested bacteria. Notably, the N/CS coating demonstrated its highest activity against B. cereus (P ≤ 0.05).

Durability of Antimicrobial Effect

In order to assess the stability of the antimicrobial activity of the coatings, the coated fabrics underwent 10 washing cycles at 60 °C, and their antibacterial performance was evaluated against the tested bacteria using the same methodology as before. The results are presented as the percentage of residual antimicrobial activity compared to unwashed fabrics (Figure 3). The CS coating retained approximately 28.25%, 15.71%, 5.9%, 3.38%, 0.4%, and 19.41% of its initial activity against B. cereus, S. aureus, E. faecalis, L. monocytogenes, E. coli, and P. aeruginosa, respectively. In contrast, the hybrid coating preserved around 100%, 17.26%, 8.55%, 2.98%, 1.38%, and 17.4% of its efficacy against B. cereus, S. aureus, E. faecalis, L. monocytogenes, E. coli, and P. aeruginosa, respectively (P ≤ 0.05).

Figure 3.

Antibacterial Activity of Coated Cotton Fabric, Fixed-coated Cotton Fabric, and Washed-coated Cotton Fabric against a: B. cereus, b: S. aureus, c: E. faecalis, d: L. monocytogenes, e: E. coli, and f: P. aeruginosa after 24 Hours of Contact

.

Antibacterial Activity of Coated Cotton Fabric, Fixed-coated Cotton Fabric, and Washed-coated Cotton Fabric against a: B. cereus, b: S. aureus, c: E. faecalis, d: L. monocytogenes, e: E. coli, and f: P. aeruginosa after 24 Hours of Contact

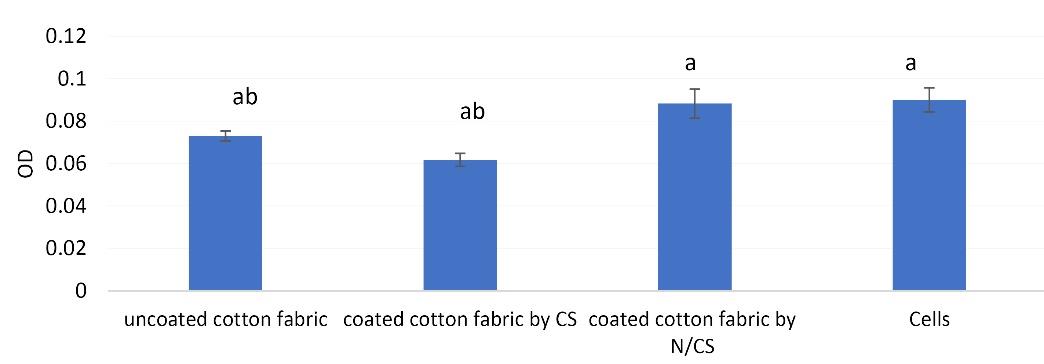

Cell Viability

The potential cytotoxicity of coated textiles intended for medical applications in contact with human skin was assessed (Figure 4). The MTT assay was employed to determine any potential toxic effect caused by the N/CS coating on fibroblast cell cultures. After 24 hours, the cultured fibroblast cells exhibited biological activity, with no discernible variation in cell viability among the tested fabric samples. However, after 7 days of cell contact with the uncoated fabric, the viability of fibroblast cells dropped to less than 18.88%. In comparison, the fabric coated with N/CS displayed no significant cytotoxicity after 7 days (P ≤ 0.05).

Figure 4.

Cytotoxic Activity of Coated Cotton Fabric, Fixed-coated Cotton Fabric, and Washed-Coated Cotton Fabric Against Fibroblasts Cells After 7 Days of Contact

.

Cytotoxic Activity of Coated Cotton Fabric, Fixed-coated Cotton Fabric, and Washed-Coated Cotton Fabric Against Fibroblasts Cells After 7 Days of Contact

Discussion

Today, the control of infectious diseases caused by pathogenic microorganisms is the ultimate goal of the World Health Organization and requires further development. Currently, there is significant interest in antimicrobial fabrics for combating the transmission of infectious diseases in medical and healthcare settings. It is widely recognized that microorganisms adhere to and proliferate on textile surfaces. Consequently, diverse materials have been employed to incorporate antimicrobial properties into textiles (25). Notably, nisin and chitosan are extensively utilized in the medical field due to their physical, chemical, non-toxic, and antimicrobial characteristics (14). The objective of this study was to evaluate the biological activities and stability of cotton textiles that were modified with nisin-chitosan. The surface modification of cotton textiles was achieved by applying the dispersions of nisin and chitosan through the padding-squeezing method. Comparing the SEM images of the samples, it was challenging to differentiate between the uncoated fabric and the fabric coated with N/CS (Figure 1). To examine the potential interaction between the chitosan film and the incorporated antimicrobial substances, FITR analysis was conducted. The analysis results indicated the presence of chitosan and nisin bands on the coated fabrics (7,14,15). Numerous studies have highlighted the remarkable antibacterial properties of both nisin and CS. Nisin effectively hinders the synthesis of bacterial cell walls by binding to lipid II. Additionally, nisin enhances the permeability of the cell membrane, leading to increased pore formations (14,26). Two principal mechanisms have been proposed to explain the antimicrobial effect of chitosan. Because of its polycationic nature, chitosan induces electrostatic accumulation on the surface of bacterial cells, ultimately leading to the disruption of bacterial metabolism. Additionally, chitosan inhibits transcription by binding to DNA molecules (1,23). Recently, hybrid complexes of metal ions and chitosan have been found to exhibit a significantly enhanced antibacterial activity compared to the individual components (3,20,23). Furthermore, the antibacterial activity was found to be directly proportional to the quantity of metal ions present in these complexes (23). Investigations into the antimicrobial properties of fabrics coated with chitosan and nisin have demonstrated their inhibitory effect on all 6 bacteria strains that were tested. Among these bacteria strains, the most notable inhibitory effect was observed against B. cereus bacteria (Figure 3). In recent times, there has been a development of chemically modified fabrics aimed at enhancing the antibacterial performance of textiles. Teli et al conducted a study exploring the use of chitosan as a penetrating agent for environmentally friendly antibacterial printing on cotton using natural dyes. The findings revealed that the printed fabric exhibited remarkable antibacterial activity against both gram-positive and gram-negative bacteria. This method holds promise for environmentally friendly printing and antibacterial treatment of textile materials (2). Rilda et al conducted a study in which they reported the augmentation of the antibacterial activity of TiO2-SiO2/chitosan-coated fabrics through the process of hydrophilization (3). Botula and Verma introduced a straightforward and expeditious approach, rooted in green chemistry principles, for coating linen fabric with chitosan-silver nanoparticles. They utilized biomolecules found in pineapple crown extract, such as glucose, fructose, and sucrose, as key components. The resulting linen fabrics, when treated with chitosan-silver nanoparticles, exhibited remarkable properties including dyeing capability, antibacterial activity, and free radical scavenging activity. Chitosan played a crucial role not only in covering and stabilizing the silver ions on the fabric surface but also in synergistically enhancing the antibacterial and antioxidant activities of the fabric surface in conjunction with the silver nanoparticles (20). Despite advancements in the production of antimicrobial fabrics, hospital textiles still face contamination during use. Consequently, regular washing is essential to prevent the transmission of pathogens. The washing stability test serves to confirm the lasting antimicrobial properties of cellulose fibers treated with a chitosan-nisin hybrid, in comparison to fibers treated solely with chitosan, against the targeted bacterial strains (Figure 3). The incorporation of nisin has enhanced the stability of the antimicrobial property, even after repeated washing of the hybrid-coated fibers. Gouda and Hebeish successfully synthesized CuO-chitosan nanocomposites and characterized them using transmission electron microscopy (TEM) and SEM with energy dispersive x-ray spectroscopy (EDS) mode. These nanocomposites were then applied to cotton fabrics, and the resulting treated fabrics were compared to fabrics coated with chitosan nanoparticles in terms of their antibacterial activity. The antibacterial coatings on the fabrics demonstrated consistent performance even after undergoing 30 washing cycles (19). Furthermore, the potential cytotoxicity of coated textiles intended for medical applications and their contact with human skin was assessed (Figure 4). The MTT assay was employed to evaluate the potential toxicity that the N/CS coating may induce in fibroblast cell cultures. Notably, after a 7-day period, the fabric coated with N/CS exhibited no significant cytotoxic effect. This can be attributed to the antioxidant property of chitosan, which effectively hinders the generation of free radicals beyond the threshold of oxidative stress (23).

Conclusion

Antibacterial and non-toxic textiles suitable for hospital use were achieved by applying chitosan-nisin antimicrobial coatings onto cotton fabrics. The combination of nisin and chitosan exhibited synergistic effects, resulting in enhanced antibacterial efficacy against all tested bacteria. The antimicrobial properties of the coated fabrics remained stable even after multiple washing cycles at 60 °C, which aligns with the standard washing practices in hospitals. Moreover, the presence of chitosan and nisin effectively mitigated any potential risks to human health. The pad-dry-cure method employed in the production of these antimicrobial textiles demonstrated significant potential for use in hospital settings, as it offers a straightforward process, increased antimicrobial effectiveness, and remarkable washing durability, thereby reducing the risk of infectious disease transmission.

Acknowledgments

Authors gratefully acknowledge the generous cooperation of Nano Structured Coatings Institute, Yazd Payame Noor University, Yazd, Iran. We gratefully thank the people of Stem Cell Biology Research Center (SCBRC), Yazd Reproductive Sciences Institute, Shahid Sadoughi University of Medical Sciences Yazd, Iran, especially Dr Habib Nikukar andDr. Behrouz Aflatoonian for their collaboration.

Authors’ Contribution

Investigation: Mahboubeh Mirhosseini, Maedeh Afzali.

Methodology: Mahboubeh Mirhosseini, Maedeh Afzali, Hosein Molla Hoseini.

Project Administration: Mahboubeh Mirhosseini, Hosein Molla Hoseini.

Resources: Mahboubeh Mirhosseini, Maedeh Afzali, Hosein Molla Hoseini.

Software: Maede Afzali, Mahboubeh Mirhosseini.

Supervision: Mahboubeh Mirhosseini, Hosein Molla Hoseini.

Validation: Mahboubeh Mirhosseini, Maede Afzali.

Visualization: Mahboubeh Mirhosseini, Maedeh Afzali, Sara Khaleghizadeh.

Writing–original draft: Mahboubeh Mirhosseini.

Writing–review & editing: Mahboubeh Mirhosseini, Sara Khaleghizadeh.

Competing Interests

All authors have no conflict of interest to report.

References

- Benltoufa S, Miled W, Trad M, Slama RB, Fayala F. Chitosan hydrogel-coated cellulosic fabric for medical end-use: antibacterial properties, basic mechanical and comfort properties. Carbohydr Polym 2020; 227:115352. doi: 10.1016/j.carbpol.2019.115352 [Crossref] [ Google Scholar]

- Teli MD, Sheikh J, Shastrakar P. Exploratory investigation of chitosan as mordant for eco-friendly antibacterial printing of cotton with natural dyes. J Text 2013; 2013:320510. doi: 10.1155/2013/320510 [Crossref] [ Google Scholar]

- Rilda Y, Safitri R, Agustien A, Nazir N, Syafiuddin A, Nur H. Enhancement of antibacterial capability of cotton textiles coated with TiO2–SiO2/chitosan using hydrophobization. J Chin Chem Soc 2017; 64(11):1347-53. doi: 10.1002/jccs.201700165 [Crossref] [ Google Scholar]

- Xu J, Jiang SX, Peng L, Wang Y, Shang S, Miao D. AgNps-PVA–coated woven cotton fabric: preparation, water repellency, shielding properties and antibacterial activity. J Ind Text 2019; 48(10):1545-65. doi: 10.1177/1528083718764908 [Crossref] [ Google Scholar]

- Venkatram M, Narasimha Murthy HNR, Gaikwad A, Mankunipoyil SA, Ramakrishna S, Ayalasomayajula Ratna P. Antibacterial and flame retardant properties of Ag-MgO/nylon 6 electrospun nanofibers for protective applications. Cloth Text Res J 2018; 36(4):296-309. doi: 10.1177/0887302x18783071 [Crossref] [ Google Scholar]

- Hanczvikkel A, Víg A, Tóth Á. Survival capability of healthcare-associated, multidrug-resistant bacteria on untreated and on antimicrobial textiles. J Ind Text 2019; 48(7):1113-35. doi: 10.1177/1528083718754901 [Crossref] [ Google Scholar]

- Cé N, Noreña CPZ, Brandelli A. Antimicrobial activity of chitosan films containing nisin, peptide P34, and natamycin. CyTA J Food 2012; 10(1):21-6. doi: 10.1080/19476337.2010.537371 [Crossref] [ Google Scholar]

- Gaffer HE, Gouda M, Abdel-Latif E. Antibacterial activity of cotton fabrics treated with sulfadimidine azo dye/chitosan colloid. J Ind Text 2013; 42(4):392-9. doi: 10.1177/1528083712441959 [Crossref] [ Google Scholar]

- Montaser AS, Mahmoud FA. Preparation of chitosan-grafted-polyvinyl acetate metal nanocomposite for producing multifunctional textile cotton fabrics. Int J Biol Macromol 2019; 124:659-66. doi: 10.1016/j.ijbiomac.2018.11.254 [Crossref] [ Google Scholar]

- Barnabas J, Miraftab M, Qinand Y, Changjun Z. Evaluating the antibacterial properties of chitosan fibres embedded with copper ions for wound dressing applications. J Ind Text 2014; 44(2):232-44. doi: 10.1177/1528083713483782 [Crossref] [ Google Scholar]

- Thomas V, Bajpai M, Bajpai SK. In situ formation of silver nanoparticles within chitosan-attached cotton fabric for antibacterial property. J Ind Text 2011; 40(3):229-45. doi: 10.1177/1528083710371490 [Crossref] [ Google Scholar]

- Erdogan S. Textile finishing with chitosan and silver nanoparticles against Escherichia coli ATCC 8739. Trakya University Journal of Natural Sciences 2020; 21(1):21-32. doi: 10.23902/trkjnat.641367 [Crossref] [ Google Scholar]

- Soykan Ş, Seventekin N, Özdoğan E, Kocatürk Z. Production of multifunctional woven cotton fabrics by a single step finishing process. Textile and Apparel 2017; 27(3):266-74. [ Google Scholar]

- Qi X, Poernomo G, Wang K, Chen Y, Chan-Park MB, Xu R. Covalent immobilization of nisin on multi-walled carbon nanotubes: superior antimicrobial and anti-biofilm properties. Nanoscale 2011; 3(4):1874-80. doi: 10.1039/c1nr10024f [Crossref] [ Google Scholar]

- Salmieri S, Islam F, Khan RA, Hossain FM, Ibrahim HMM, Miao C. Antimicrobial nanocomposite films made of poly(lactic acid)-cellulose nanocrystals (PLA-CNC) in food applications: part A—effect of nisin release on the inactivation of Listeria monocytogenes in ham. Cellulose 2014; 21(3):1837-50. doi: 10.1007/s10570-014-0230-6 [Crossref] [ Google Scholar]

- Colpankan Gunes O, Ziylan Albayrak A. Antibacterial Polypeptide nisin containing cotton modified hydrogel composite wound dressings. Polym Bull (Berl) 2021; 78(11):6409-28. doi: 10.1007/s00289-020-03429-4 [Crossref] [ Google Scholar]

- Chi H, Holo H. Synergistic antimicrobial activity between the broad spectrum bacteriocin garvicin KS and nisin, farnesol and polymyxin B against gram-positive and gram-negative bacteria. Curr Microbiol 2018; 75(3):272-7. doi: 10.1007/s00284-017-1375-y [Crossref] [ Google Scholar]

- Małaczewska J, Kaczorek-Łukowska E. Nisin-A lantibiotic with immunomodulatory properties: a review. Peptides 2021; 137:170479. doi: 10.1016/j.peptides.2020.170479 [Crossref] [ Google Scholar]

- Gouda M, Hebeish A. Preparation and evaluation of CuO/chitosan nanocomposite for antibacterial finishing cotton fabric. J Ind Text 2010; 39(3):203-14. doi: 10.1177/1528083709103142 [Crossref] [ Google Scholar]

- Butola BS, Verma D. Facile synthesis of chitosan-silver nanoparticles onto linen for antibacterial activity and free-radical scavenging textiles. Int J Biol Macromol 2019; 133:1134-41. doi: 10.1016/j.ijbiomac.2019.04.186 [Crossref] [ Google Scholar]

- Wei Z, Xinlan D, Jinjie Z. Properties of cotton fabric modified with a chitosan quaternary ammonium salt nanoparticle. Fibres Text East Eur 2018; 26(4):116-21. doi: 10.5604/01.3001.0012.1322 [Crossref] [ Google Scholar]

- Mirhosseini M, Afzali M, Ghasemabadi Ghotbuddini S. Characterization and antibacterial activity of nanochitosan-nisin biocomposite film prepared from shrimp shells. J Agric Sci Technol 2023; 25(2):341-54. doi: 10.52547/jast.25.2.341 [Crossref] [ Google Scholar]

- Petkova P, Francesko A, Fernandes MM, Mendoza E, Perelshtein I, Gedanken A. Sonochemical coating of textiles with hybrid ZnO/chitosan antimicrobial nanoparticles. ACS Appl Mater Interfaces 2014; 6(2):1164-72. doi: 10.1021/am404852d [Crossref] [ Google Scholar]

- Mirhosseini M, Barzegari Firouzabadi F. Preparation of ZnO-polystyerne composite films and investigation of antibacterial properties of ZnO-polystyerne composite films. Iran J Pathol 2014; 9(2):99-106. [ Google Scholar]

- Aboelmagd LA, Tolba E, AbdelAziz ZA. Chitosan-organosilica hybrid decorated with silver nanoparticles for antimicrobial wearable cotton fabrics. Polym Bull (Berl) 2023; 80(4):4229-43. doi: 10.1007/s00289-022-04250-x [Crossref] [ Google Scholar]

- Saini S, Sillard C, Belgacem MN, Bras J. Nisin anchored cellulose nanofibers for long term antimicrobial active food packaging. RSC Adv 2016; 6(15):12422-30. doi: 10.1039/c5ra22748h [Crossref] [ Google Scholar]